Email: [email protected] Phone: (+86) 134 1323 8643

Centering in CNC machining is the process of accurately locating the reference point of a workpiece. This is crucial for ensuring precise and error-free machining operations. If centering is not done correctly, it can lead to significant errors or even scrapped parts. Therefore, mastering center techniques is an essential skill for every CNC operator.

Common Centering Methods

There are three primary methods for centering workpieces in CNC machining:

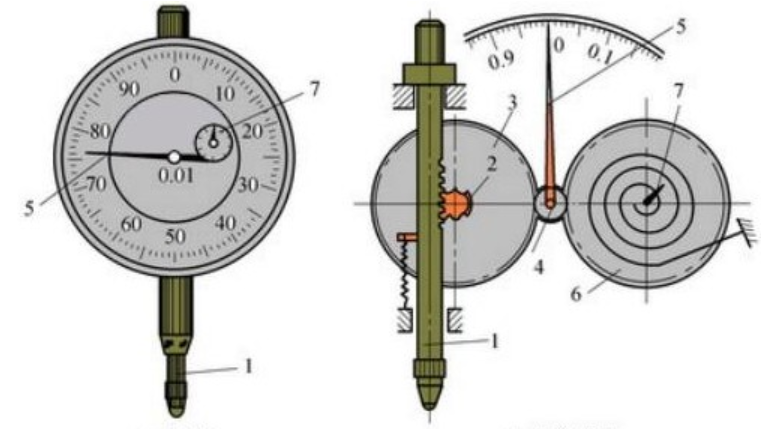

1.Dial Indicator (DTI) Center: This method utilizes a dial indicator mounted on the machine spindle to measure the distance between the spindle centerline and the workpiece surface. While effective, DTI centering requires manual operation, making it time-consuming and susceptible to human error. Its limitations have led to its gradual decline in popularity.

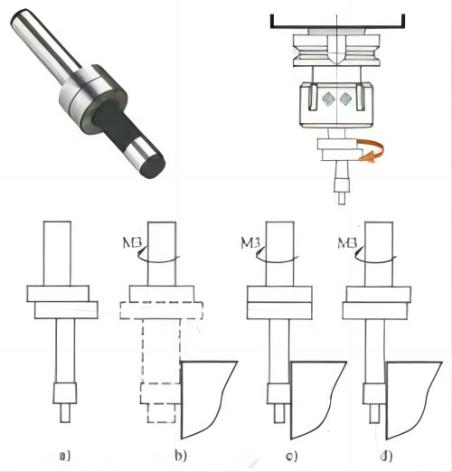

2.Edge Finder Center: An edge finder, also known as a centering rod, is used to locate the edges of the workpiece. By touching the edge finder to the workpiece and recording the machine coordinates, the center can be calculated. However, this method relies on visual judgment and is limited to workpieces with edges larger than 10mm in diameter.

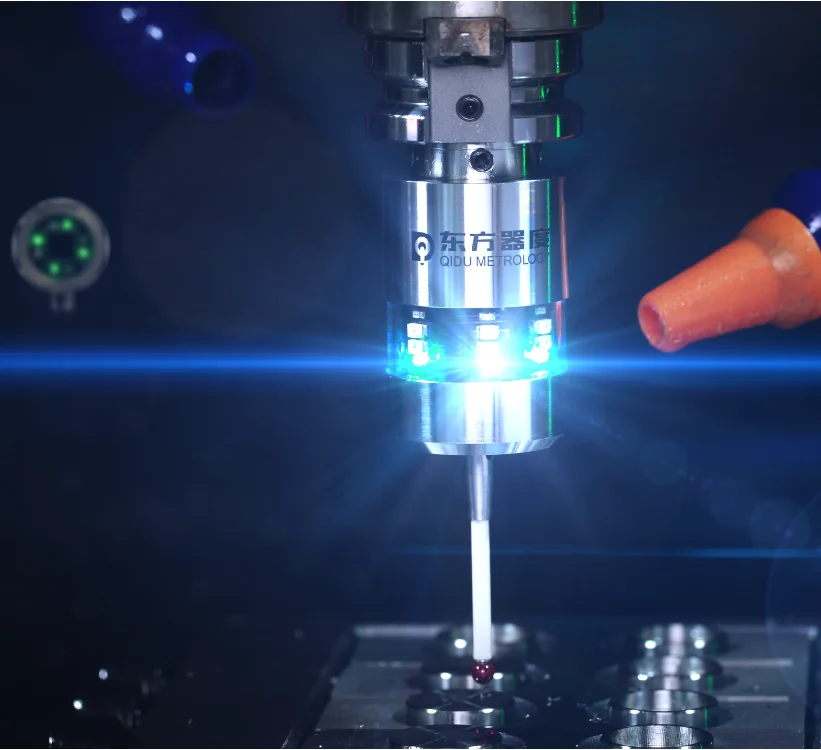

3.Machine Tool Probe Center: This method employs a machine tool probe, which is a highly accurate touch sensor integrated into the CNC machine. The probe is programmed to touch the workpiece at multiple points, and the machine’s software calculates the center based on the recorded coordinates. This method offers superior precision and eliminates human error, making it the preferred choice for modern CNC machining.

Qidu Metrology Machine Tool Probes: Precision and Versatility

Qidu Métrologie offers a range of high-precision machine tool probes that meet the demands of modern CNC machining. These probes boast repeatability of up to 1 µm, enabling precise centering even for small workpieces. They can measure holes with diameters as small as 2mm and offer interchangeable styli to suit various applications. With customizable stylus lengths, Qidu Metrology probes cater to a wide range of machining needs.

Conclusion

Centering is a fundamental aspect of CNC machining, ensuring accurate and error-free operations. While traditional methods like DTI and edge finder center have limitations, machine tool probe center has emerged as the preferred choice due to its superior precision and reliability. Qidu Metrology’s machine tool probes offer exceptional accuracy, versatility, and durability, making them an invaluable asset for modern CNC machining setups.

Katrina

Ingénieur commercial en mécanique avec plus de 10 ans d'expérience dans l'industrie manufacturière. Compétent dans l'élaboration et l'exécution de stratégies de vente, l'établissement de relations avec les clients et la conclusion de transactions. Maîtrise d'une variété d'outils de vente et de marketing, notamment les logiciels CRM, les outils de génération de leads et les médias sociaux. Je suis capable de travailler de manière indépendante et au sein d'une équipe pour atteindre les buts et objectifs de vente. Dédié à l’amélioration continue et à l’apprentissage de nouvelles techniques de vente.